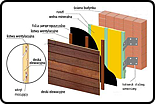

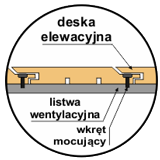

Thermo wood (wood thermally-modified) is manufactured according to technology, which uses only high temperatures without additional chemicals. Such technology depends on changing the properties of wood and that increases theresistance to biological conditions and water. The timber which has been treated with high temperature is more stable and resistant to humidity change in environment.

The timber is being treated with the temperature between170°C and 230°C, inert gas and water. By-products generated during thermal modification are gases, which burn. In this way the whole process is totally ecological.

The results of thermal modification are: increased resistance and special dark brown shade, which are confusingly similar to egzotic types of timber.

What is more important, the change of colour takes place on the whole section of wood and that enables manufacturing profile work-piece shapes. The oak is very interesting example, where the appropriate directing of the process gives the possibility to obtain very similar wood to black oak. Black oak is very rare, expensive and difficult to work with. But on the other hand the black oak is very desired material for florring contractors. Using thermo-wood helps to avoid alll those problems.

THE MOST IMPORTANT CHANGES OF WOOD PROPERTIES AFTER THERMAL MODIFICATION PROCESS:

- increased resistance to humidity( lower than 50 % humidity equivalent to raw wood on grounds of changing cell structure of the wood);

- increased dimensional stability (swelling, shrinkage of the wood is 50 % lower than this of the raw material);

- decreased absorption;

- better properties of thermal insulation;

- increased resistance to fungi;

- partial removal of volatile substances and resin ( considers mainly softwood )

THERMO-WOOD does not require chemical impregnation. The conservation proces is the same like with other types of wood. Thermo-wood can be coated, stained, oiled or waxed. We advice using products which have pigment or UV filter, in order to avoid greying and fading which could be caused by UV radiation.

The good effect can be obtained by using oils and waxes, which exposes wood grains and colour of the wood.