Assembly system with visible fastening elements

Groundwork for terrace must be prepared earlier by spreading concrete or other smoothing technique (like stones or sand).

If it is not possible to level the area, fixed and adjustable brackets should be used for assembling the beams. They will reduce the differences in level.

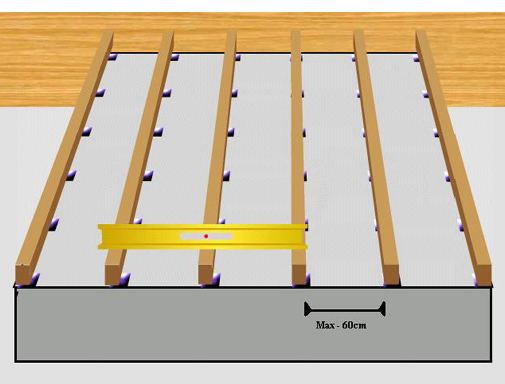

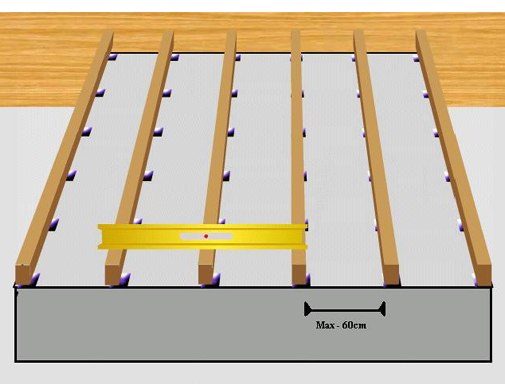

On well-prepared ground, rubber pads should be distributed – only in case of isolation, which is laid beneath the beams. Next, we lay out the wooden beams in the distance 50-60 cm max. Their cross-section is chosen according to conditions on the ground of the laid terrace. The whole under-construction must be levelled in a way to reach 0,5 %-0,5cm per running meter of fall to the side of drain.

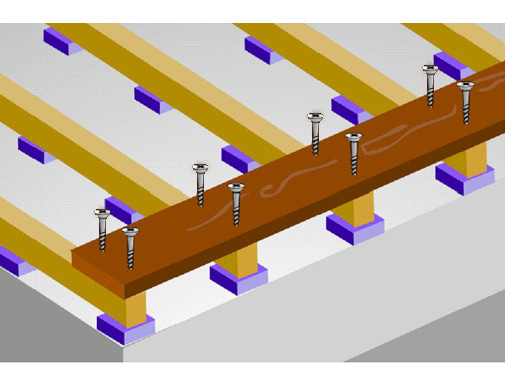

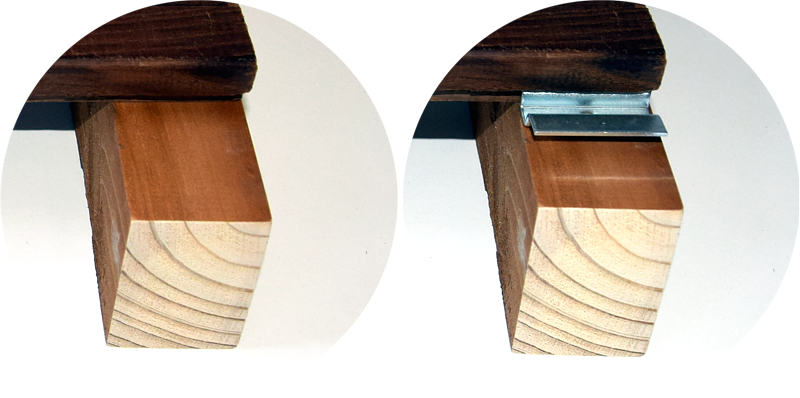

The next stage is laying the terrace panels onto the beams and fastening them with special stainless steel screws (made for terraces). Stainless steel prevents from corrosion of the screws, which results in that there is no damage in terrace panels and also they don’t make the terrace panels dirty. Certain types of exotic wood, like bangkirai, consist of tannin acid, which can speed up the natural corrosion of ordinary steel screws. Additional valour of screws used by our company is the fact that they are equipped with “cut” drills – self-drilling and thanks to that you do not need to pre-drill the panels.

Screws used by us have T-STAR plus socket – star bit, which allows to undo the screw and screw it again without fear of destroying the screw itself. This method is very special, quick and clean.

Terrace panels are fastened with screws to the beams from the top of each board. Advised distances for fastening the screws counting from the edge of the board shouldn’t be longer than 5-7 cm, in order to avoid probable deforming its edges and minimum 2 cm from the side of the board, because the closer to the edge the better chance the board cracks. When we take into consideration a minimal length of the screws it should be equal of the double thickness of the board, and screw diameter should equal 5 mm.

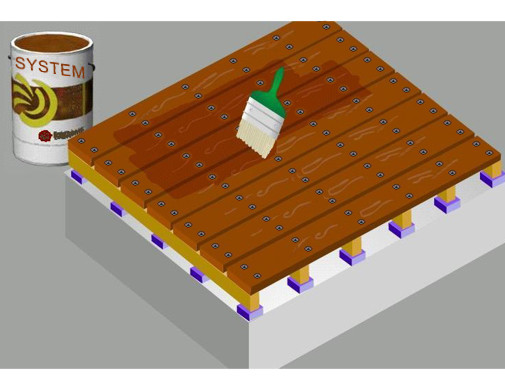

If there are any small scratches and damages during the assembly of terrace we can refresh and smooth the surface with the help sandpaper (density 200). It is important to polish the panels along the graining.

When the assembly is finished the terrace should be dusted and cleaned.

The next step will be coating the boards with the thin layer of oil. It should be done with a brush. After coating with oil, we must wait 24 hours. The oiling process ought to be done twice. After that the surface of the terrace should be wiped with the cotton cloth.

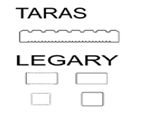

Assembly system without visible fastening elements

Groundwork for terrace must be prepared earlier by spreading concrete or other smoothing technique (like stones or sand).

If it is not possible to level the area, fixed and adjustable brackets should be used for assembling the beams. They will reduce the differences in level.

On well-prepared ground, rubber pads should be distributed – only in case of isolation, which is laid beneath the beams. Next, we lay out the wooden beams in the distance 50-60 cm max. Their cross-section is chosen according to conditions on the ground of the laid terrace. The whole under-construction must be levelled in a way to reach 0,5 %-0,5cm per running meter of fall to the side of drain.

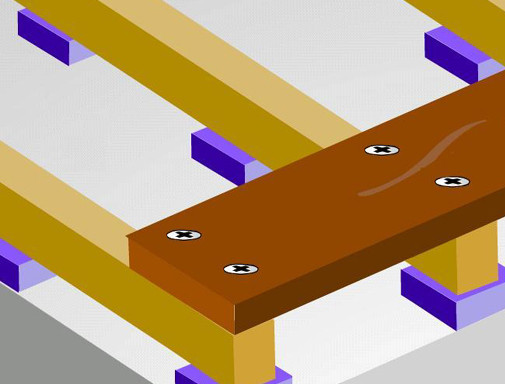

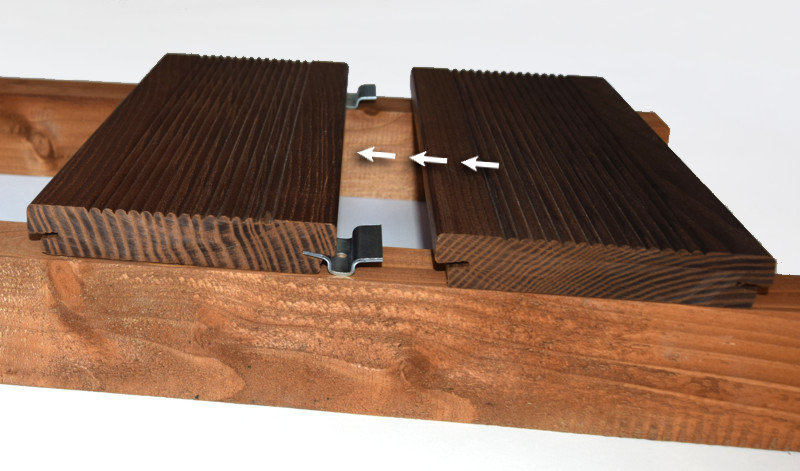

The next stage is laying the terrace panels onto the beams and preparing the system plates.

The outer part of the plate fits into side grooves – the cutters of the board, and then it is screwed to a beam.

The next terrace board is put to the second outer side of plate. Those operations are done repetitively.

This way of assembling the terrace allows to gain beautiful wooden space without the heads of screws and that influences the aesthetics of the terrace.

If there are any small scratches and damages during the assembly of terrace we can refresh and smooth the surface with the help sandpaper (density 200). It is important to polish the panels along the graining.

When the assembly is finished the terrace should be dusted and cleaned.

The next step will be coating the boards with the thin layer of oil. It should be done with a brush. After coating with oil, we must wait 24 hours. The oiling process ought to be done twice. After that the surface of the terrace should be wiped with the cotton cloth.